We create Reliable

High-performance fluid control solutions

Focusing on the R&D and manufacturing of high-performance valves, we support customized fluid control solutions.

Independent R&D

Relying on independent research and development, we provide customers with reliable fluid control solutions.

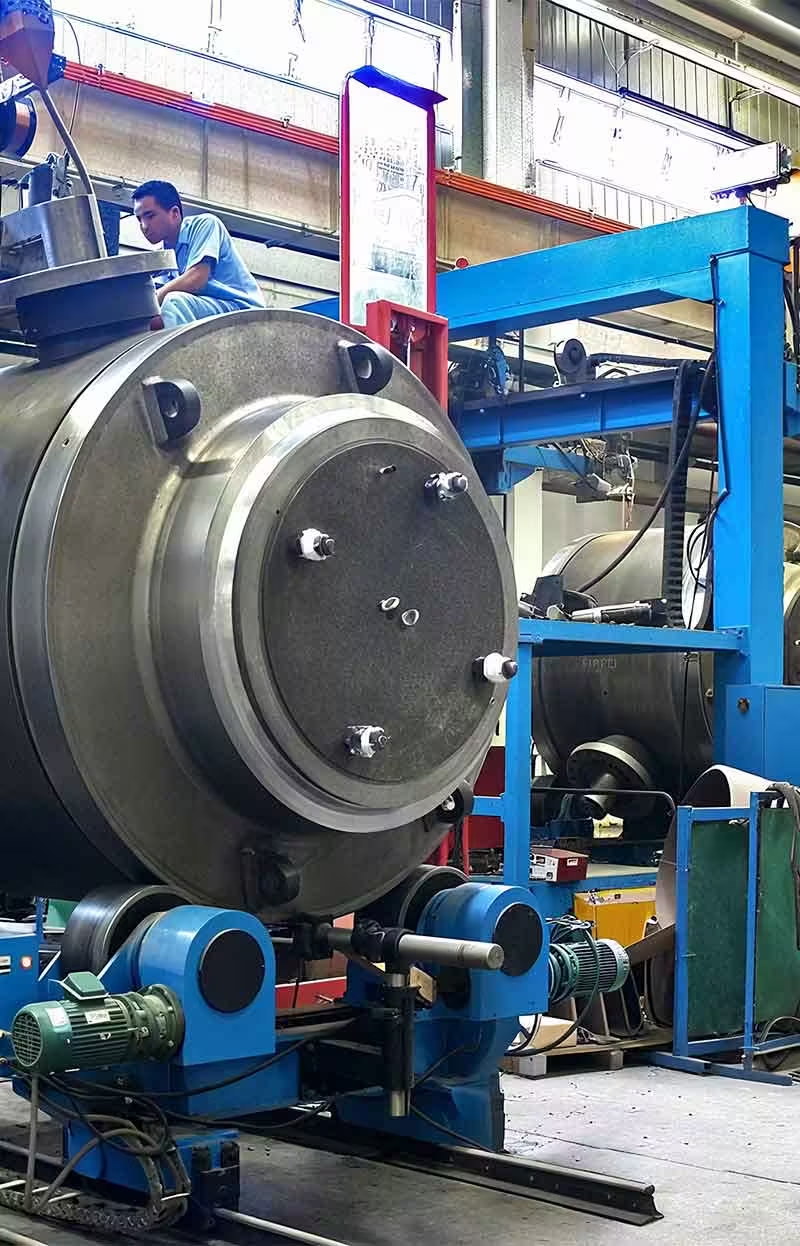

Precision Manufacturing

Rigorous production management enables accurate control of all manufacturing processes.

Ready to take your flow control to the next level?

High-performance valves and precision solutions for energy, petrochemical, power, and marine industries.

Quality Is Our PromiseInnovation Is Our Path

ABOUT US

Work with you to create a safe and efficient future

With strict end-to-end quality control, EF swiftly establishing a robust presence both in the domestic market and across international borders. The products are now exported to over 30 countries and regions worldwide, from North America to Southeast Asia, earning high praise from global customers for reliability and performance. This success is underpinned by our comprehensive quality management system, certified by ISO9001, OHSAS18001,ISO14001,TSG, API 6D/607, CE, CCS, DNV-GL, BV, RINA, LR, ABS and 3A corporate credit certification, ensuring consistent excellence in every valve produced.

OUR SERVICES

One-stop valve service solutions

More than just products, we provide comprehensive services

Technical Consulting

Our expert team provides fluid operating condition analysis and valve selection recommendations, helping customers mitigate procurement risks.

Customized Solutions

We offer dedicated design and custom manufacturing services for special operating conditions (such as high and low temperatures).

Spareparts Replacement

We provide standardized storage and management services to ensure valves and components are always in optimal condition before commissioning.

Technical Support

Remote diagnostics and online support provide rapid response to on-site customer issues, providing fault diagnosis and repairs to minimize downtime.

Lifecycle Benefits

Through our full lifecycle services, we extend valve life, reduce operating and maintenance costs, and achieve optimal return on investment.

Troubleshooting

We provide a 24/7 rapid response mechanism for unexpected failures, ensuring safe operation in critical conditions and minimizing downtime losses.

Why Choose Us

A Trusted Choice In Fluid Control

As a professional industrial valve manufacturer, EF has gained deep trust from customers by virtue of its independent R&D capabilities, precision production processes, and full-cycle service system. EF remains committed to technological breakthroughs and quality refinement, and more importantly, we take customer needs as the core, providing customized, efficient, and stable overall fluid control solutions to safeguard the safe operation of fluid systems in industrial scenarios.

For valve service, email us!

Independent R&D

EF Valve boasts a dedicated R&D team and professional testing platform, focusing on core areas. The persistent innovation has led to the continuous acquisition of numerous intellectual property rights and patents, laying a solid technical foundation for reliable flow control solutions.

Multiple Certifications

EF holds authoritative certifications including ISO9001 (quality management), ISO14001 (environmental management), and ISO45001 (occupational health and safety). Additionally, EF obtained international technical certifications such as API 6D, CE, TSG, CCS, and DNV-GL, fully meeting strict quality and safety requirements for global application scenarios.

Strict Quality Inspection

Equipped with CL2500-class cryogenic testing equipment, a professional physical and chemical laboratory, and advanced non-destructive testing tools, EF implements full-process quality control—covering raw material screening, in-production monitoring, and finished product verification—to ensure every valve meets consistent high standards.

We help you achieve safer, smarter, and more

efficient flow control.

Discover how our precision valves can optimize your operations & reduce downtime.

application

Valves Designed For Various Applications

EF designs reliable flow control equipment for various industrial applications including energy, power generation, chemical processing, marine, construction and semi-conductor sectors. The application knowledge and technical expertise in flow control equipment enable us to help clients with the toughest challenges.

Petroleum Refining

Chemical Industry

Water Treatment

New Energy

Ships

Buildings

TESTIMONIALS

Find Out What Our Customers Are Saying About Us

With a sophisticated production management model, a strong R&D team, solid production technology, and reliable products of excellent quality, EF has won the favor of domestic and international customers and become a long-term and stable partner.

FAQs FOR CLIENT

Your questions, we answer

We specialize in industrial valves, including ball valves, butterfly valves, gate valves, and check valves, serving multiple industries, including power generation, petrochemicals, energy storage, marine, and nuclear power.

Our products are certified by ISO9001, API 6D, CE, TSG, CCS, and DNV, meeting international quality and safety standards.

Yes, we offer customized solutions in terms of material, structure, size, and functionality based on our customers' application requirements.

We offer a full lifecycle service, including selection consultation, installation and commissioning, on-site repairs, spare parts supply, and emergency response.

Standard product delivery typically lasts 2–4 weeks. Customized products require confirmation based on specific application conditions and requirements.

Get In Touch

Lorem ipsum dolor sit amet consectetur adipiscing elit eue mauris molestie orci eget.