Valve pressure parts produced by precision casting process,handwheel using high quality malleable iron casting and designed for easy operation with suitable torque.Clear indication with “Open”and “Close”mark.

Features And Benefits

· Valve pressure parts produced by precision casting process,handwheel using high quality malleable iron casting and designed for easy operation with suitable torque.Clear indication with “Open”and “Close”mark.

· Stem nut uses austen ductile iron,trapezoidal form thread and valve stem ensure proper torque transmission.

· Valve bonnet equipped with grease nipple,to provide periodic lubrication for smooth and easy operation.

· Gland flange and gland designed to ensure concentricity of the valve stem. Stuffing box is designed to ensure there is no external leakage for the valve,in line with environmental requirements.

· Bonnet designed with sealing surface,conforms to the American Petroleum Institute(API)standard.

· Valve flange bolts using studs for easy maintenance and removal.

· Solid stemhead forging and”T” type slotconnection withdisctoensure the integrity of the connection.

· Below DN250 uses precision casting,each batch of castings has heat number identification for easy tracing.

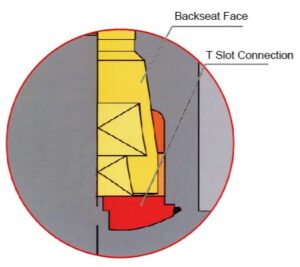

Reliable Connection Between Stem Head and Disc:

Gate valve stem adopts A182F6(1Cr13)overall forging,having strong tensile strength to ensure that the valve stem head will not shear at seized condition which may cause the disc to be trapped in the body and difficulty in removal.

Valve stem head enclosed within airtight bonnet seaing suface,to ensure no external leakage when valve infullopen position.

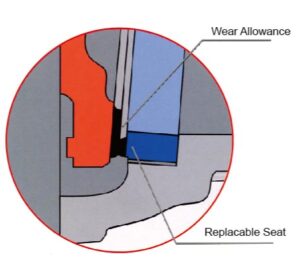

Replaceable Seat and Wear Allowance:

Gate valve seat are threaded to the valve body,design for convenient maintenance and replacementValve seat sealing surface produce by precision grinding and screwed in the body with special tools to achieve reliable seal. Dise sealing surface is wider than the valve seat sealing surface to ensure sufficient alignment between disc and seat sealing surface.After using the valve for a certain period,any minor wear and tear will not affect the integrity of the sealing surfaces for the dise and seat.

| ANSI 150 | |||||||||||||

| NPS | 2 | 2V₂ | 3 | 4 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 24 |

| L | 178 | 190 | 203 | 229 | 267 | 292 | 330 | 356 | 381 | 406 | 432 | 457 | 508 |

| H | 400 | 490 | 510 | 585 | 775 | 955 | 1160 | 1375 | 1570 | 1765 | 1980 | — | — |

| D。 | 200 | 200 | 250 | 300 | 350 | 350 | 400 | 450 | 500 | 600 | 700 | — | — |

| w. | 23 | 45 | 50 | 63 | 108 | 171 | 263 | 346 | 488 | 621 | 814 | — | — |

| PN16 | |||||||||||||

| DN | 50 | 65 | 80 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 |

| L | 250 | 265 | 280 | 300 | 350 | 400 | 450 | 500 | 550 | 600 | 650 | 700 | 800 |

| H | 415 | 450 | 530 | 605 | 850 | 1060 | 1225 | 1415 | 1630 | 1780 | 2050 | — | — |

| D。 | 240 | 240 | 280 | 300 | 350 | 400 | 450 | 500 | 500 | 600 | 720 | — | — |

| w. | 22 | 30 | 44 | 47 | 96 | 160 | 228 | 300 | 388 | 566 | 900 | — | — |

Specialization in the production of ball valves, butterfly valves, and other specialty valves for various industrial applications.

Certifications of ISO 9001, CE, API 6D, and API 607, ensuring product quality compliance with international standards.

Specialization in the production of pneumatic valve actuators, along with the provision of comprehensive automated control solutions.

Have questions about our valve? Here are some of the most frequently asked questions to help you better understand our products and services. Feel free to contact us for more details!

If you don’t find the answer you’re looking for, feel free to contact us directly—we’re here to assist you every step of the way.

We specialize in industrial valves, including ball valves, butterfly valves, gate valves, and check valves, serving multiple industries, including power generation, petrochemicals, energy storage, marine, and nuclear power.

Our products are certified by ISO9001, API 6D, CE, TSG, CCS, and DNV, meeting international quality and safety standards.

Yes, we offer customized solutions in terms of material, structure, size, and functionality based on our customers' application requirements.

We offer a full lifecycle service, including selection consultation, installation and commissioning, on-site repairs, spare parts supply, and emergency response.

Whether you need valve selection consultation, customized solutions, or after-sales technical support, our team will provide you with fast and professional service.

Email Us