Handwheel using high quality malleable iron casting and designed for easy operation with suitable torque.Clear indication with “Open” and “Close”mark. For large diameters and high pressure, option to choose “impact” type handwheel.

Features And Advantages:

· Handwheel using high quality malleable iron casting and designed for easy operation with suitable torque.Clear indication with “Open” and “Close”mark. For large diameters and high pressure, option to choose “impact” type handwheel.

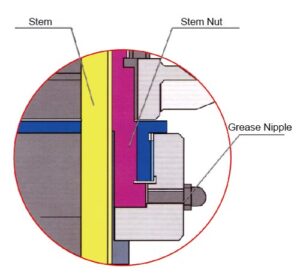

· Stem nut uses high nickel ductile iron, “T” shape screw and valve stem ensure proper torque transmission. With the increase of diameter and pressure, 1~2 thrust bearings can be added to reduce the operating torque appropriately. Grease nipple to provide periodic lubrication for smooth and easy operation.

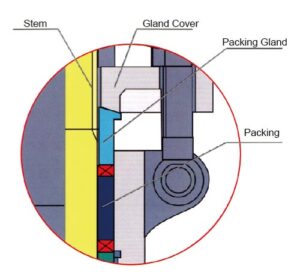

· Gland packing and gland design to ensure concentricity of the valve stem. Stuffing box designed to ensure there is no external leakage of the valve, in line with environmental requirements.

· Bonnet designed with sealing surface, conforms to the American Petroleum Institute (API) and British (BS) standards.

· Valve flange bolt using studs for easy maintenance and removal.

· Threaded seat is replaceable type, safe usage and easy maintenance.

· Below DN250 uses precision casting,each batch of castings has heat number identification for easy tracing.

Easy Torque Structure:

Handwheel torque is transmitted from the stem nut to the stem. Valve stem material using A182F6 (1 cr13) forging and conditioning treatment, hardness HB220~250. Small diameter and low pressure uses rising stem rotation structure, while large diameter uses stem nut structure.

To prevent loss of torque during transmission, stem nut uses high nickel ductile iron A439GR. D2 or copper alloy (high nickel ductile iron contains self lubrication properties), hardness is lower than the stem by approximately HB50.

Large diameter and high pressure valves are available with thrust bearing at stem nut assembly and at the same time equipped with grease nipple to provide periodic lubrication for smooth and easy operation.

Design of Leakage Prevention Stuffing Box:

Valve packing material is a combination of flexible and braided graphite, both having good sealing performance and strength. Gland Cover and Packing Gland is split type design, spherical contact to maintain concentricity. This ensure no scratches on the valve stem during operation. Packing Gland designed with steps to prevent sendiments entering into the stuffing box. Valve stem threaded portion designed to be above of the packings, to prevent any damage. Such packing box ensure no external leakage, meeting environmental protection requirement.

Sealing Structure Conforms to API and BS standards:

Bonnet designed with back seat seal, in line with the American Petroleum Institute (API) and British (BS) standards.

Valve stem uses 1 cr13 or 2 cr13 stainless steel, achieved minimum hardness HB200 after tempering process. Surface roughness after cylindrical grinding process is Ra0.8. Integral forged valve stem head provides high tensile strength to prevent fracture which may caused by stress concentration. Valve bonnet has a replaceable seal structure, which provide reliable sealing by forming with the valve stem when the valve is full open position.

Connection Structure Between Valve Stem and Disc (Plug):

Stem head and spherical structure of “T” type connection, with a threaded gland over it and spot welded for a rigid connection.

Valve stem head is spherically designed with specific hardness. Thrust pad of soft material inside the disc (plug) provide a gap between the stem head and gland. Sealing surface of the disc (plug) is tapered. This ensure better alignment with the seat sealing surface during thrust movements to achieve reliable seal. A tapered tolerance of 0.5 ~ 1 between the seat and disc (plug) provides a secondary sealing. This can be more suitable for high pressure applications.

Specialization in the production of ball valves, butterfly valves, and other specialty valves for various industrial applications.

Certifications of ISO 9001, CE, API 6D, and API 607, ensuring product quality compliance with international standards.

Specialization in the production of pneumatic valve actuators, along with the provision of comprehensive automated control solutions.

Have questions about our valve? Here are some of the most frequently asked questions to help you better understand our products and services. Feel free to contact us for more details!

If you don’t find the answer you’re looking for, feel free to contact us directly—we’re here to assist you every step of the way.

We specialize in industrial valves, including ball valves, butterfly valves, gate valves, and check valves, serving multiple industries, including power generation, petrochemicals, energy storage, marine, and nuclear power.

Our products are certified by ISO9001, API 6D, CE, TSG, CCS, and DNV, meeting international quality and safety standards.

Yes, we offer customized solutions in terms of material, structure, size, and functionality based on our customers' application requirements.

We offer a full lifecycle service, including selection consultation, installation and commissioning, on-site repairs, spare parts supply, and emergency response.

Whether you need valve selection consultation, customized solutions, or after-sales technical support, our team will provide you with fast and professional service.

Email Us