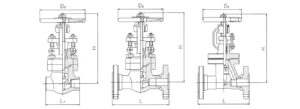

Forged steel globe valve is suitable for the nominal pressure for PN2.5, 4.0 10.0 14.0 25.0 MPA, nominal diameter from DN10 ~ 50 mm suitable for high temperature and pressure. Application includes hydrogen-nitrogen mixture gas, water, urea and methylamine liquid and etc.

Features and Advantages:

· Forged steel globe valve is suitable for the nominal pressure for PN2.5, 4.0 10.0 14.0 25.0 MPA, nominal diameter from DN10 ~ 50 mm suitable for high temperature and pressure. Application includes hydrogen-nitrogen mixture gas, water, urea and methylamine liquid and etc.

· Stem and stem nut designed with trapezoidal thread movements. Type of thread comply to GB5796. Stem head design has a tapered tight seat seal to ensure no external leakage.

· Body, bonnet and other pressure parts using integral forging (mould forging). Flange end connection available with welded option. Type of connection available includes flange, socket weld and internal threaded connections.

· Seat and body connection can be threaded, welded or formed by direct stelliting on to the valve body. For stainless steel body, seat can be formed by direct machining on the body. Stellite thickness is greater than or equal to 2 mm.

· For nominal pressure greater than 15.0 Mpa, forged steel valves designed with self-tightening seal structure, stuffing box and disc adopt overall forging machining process. Guaranteed to withstand high pressure applications.

| ANSI 150 | ||||||

| NPS | I₂ | 45720 | 1 | 0.01 | 1/₂ | 2 |

| L | 108 | 117 | 127 | 140 | 165 | 203 |

| H | 165 | 195 | 250 | 250 | 290 | 310 |

| D。 | 100 | 125 | 160 | 160 | 180 | 200 |

| W | 6.9 | 9.8 | 13.5 | 19.5 | 28.5 | 30.3 |

| ANSI 300 | ||||||

| NPS | /₂ | % | 1 | 0.01 | 1/₂ | 2 |

| L | 152 | 178 | 203 | 216 | 229 | 267 |

| H | 165 | 195 | 250 | 250 | 290 | 310 |

| D。 | 100 | 125 | 160 | 160 | 180 | 200 |

| W | 7.7 | 11.3 | 16.8 | 21.2 | 32.6 | 35 |

| ANSI 600 | ||||||

| NPS | I₂ | 45720 | 1 | 1/。 | 1/₂ | 2 |

| L | 165 | 190 | 216 | 229 | 241 | 292 |

| H | 165 | 195 | 250 | 250 | 290 | 310 |

| D。 | 100 | 125 | 160 | 160 | 180 | 200 |

| W | 7.8 | 12.5 | 17.5 | 23.5 | 38.5 | 42.2 |

| ANSI 150-800 | ||||||||

| NPS | / | % | ₂ | 3/ | 1 | 0.01 | 1₂ | 2 |

| L | 79 | 79 | 79 | 92 | 111 | 120 | 152 | 172 |

| H | 155 | 155 | 155 | 160 | 195 | 265 | 265 | 300 |

| D。 | 100 | 100 | 100 | 100 | 125 | 160 | 160 | 180 |

| W | 2.2 | 2.2 | 2 | 1.9 | 2.4 | 3.5 | 8 | 8.6 |

Specialization in the production of ball valves, butterfly valves, and other specialty valves for various industrial applications.

Certifications of ISO 9001, CE, API 6D, and API 607, ensuring product quality compliance with international standards.

Specialization in the production of pneumatic valve actuators, along with the provision of comprehensive automated control solutions.

Have questions about our valve? Here are some of the most frequently asked questions to help you better understand our products and services. Feel free to contact us for more details!

If you don’t find the answer you’re looking for, feel free to contact us directly—we’re here to assist you every step of the way.

We specialize in industrial valves, including ball valves, butterfly valves, gate valves, and check valves, serving multiple industries, including power generation, petrochemicals, energy storage, marine, and nuclear power.

Our products are certified by ISO9001, API 6D, CE, TSG, CCS, and DNV, meeting international quality and safety standards.

Yes, we offer customized solutions in terms of material, structure, size, and functionality based on our customers' application requirements.

We offer a full lifecycle service, including selection consultation, installation and commissioning, on-site repairs, spare parts supply, and emergency response.

Whether you need valve selection consultation, customized solutions, or after-sales technical support, our team will provide you with fast and professional service.

Email Us