Single-acting pneumatic actuators use compressed air to drive one direction of motion (e.g., valve opening), while relying on springs, gravity, etc., for reset (e.g., valve closing).

Featuring compact design, fail-safe functionality (critical for emergency shutoff), and lower air consumption vs. double-acting types. Widely applied in petrochemical safety loops, water treatment pipelines, and HVAC systems—scenarios demanding reliable automatic reset to protect equipment and processes.

Features

· Just to install the company’s spring to make double action into single action with the same design dimensions.

· NAMUR (VDE3845) standard interface can connect with a variety of control devices simply.

· Standard size base link is in line with the ISO5211, DIN3337 standard, can be directly linked with the valve.

· Retrofitting the special stand of our company will be able to achieve the freedom of the cylinder opening function.

· Diameter mirror processing and use special hard-oxidation process, reduce the frictional resistance and wear parts effectively, switch to achieve 500,000 times without wear and tear parts, ensure the product service life and output efficiency.

· Single-action cylinder using a spring-type structure to achieve the miniaturization of the cylinder. To use combination of a spring structure and the number of springs can be adjusted to achieve the requirements of a wide range of output torque.

· Reasonable design, the cylinder lightweight. Reduce weight about 30% compared with similar products.

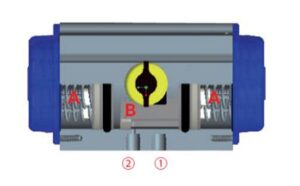

Operating Principle

1. Air to Port 2 forces the pistons outwards, causing the springs to compress, the pinion turns counterclockwise while air is being exhausted from Port 1.

2.In the event of loss of air pressure or power, the stored energy in the springs forces the pistons inwards, causing the pinion turns clockwise

while air is being exhausted from Port 2, and air to Port 1 can accelerate closing the valve.

3. By changing the installation of the direction of piston can make the cylinder air to open or close.

4. Air consumption (L/min)=air volume opening x (air supply(kpa)+101.3)÷101.3 x action cycle times(/min).

Operating Conditions

| Operating media | Dry or lubricated air,or inertia gases.Impurity particle is less than 30μm. | |||||||||

| Standard operating pressure | 0.4Mpa | |||||||||

| Operating pressure | 0.25~0.8Mpa | |||||||||

| Actuator body pressure | 1.2Mpa | |||||||||

| Rotating Angle | 90°±5° | |||||||||

| Operating environment | -20~80℃(Non-freezing fluid)indoor | |||||||||

| Connection base | or outdoor.In line with the ISO5211,DIN3337 | |||||||||

| Control device to connect | Measure up to NAMUR(VDINDE3845) | |||||||||

Output torque(double-acting)

| A | B | C | D | E | F | G | HH1 | I | N | Connecting flange:ISO 5211 | Air Cnnerction | ||||

| Model | Unit:mm | J | K | L | M | ||||||||||

| PLE-052 | 184 | 77 | 38 | 97 | 25 | 44 | 16 | 80 | 30 | 11 | F05 | F03 | M6*10 | M5*8 | NPT/。” |

| PLE-070 | 209 | 100 | 51 | 120 | 35 | 53 | 16 | 80 | 30 | 14 | F07 | F05 | M8*15 | M6*10 | |

| PLE-085 | 230 | 115.5 | 56 | 135.5 | 35 | 61.5 | 16 | 80 | 30 | 14 | F07 | F05 | M8*15 | M6*10 | |

| PLE-095 | 255 | 127.5 | 67 | 147.5 | 35 | 66.5 | 21 | 80 | 30 | 19 | F07 | F05 | M8*15 | M6*10 | |

| PLE-105 | 271 | 134 | 57.5 | 154 | 46 | 64 | 26 | 80 | 30 | 19 | F10 | F07 | M10*16 | M8*13 | |

| PLE-125 | 299 | 156 | 67.5 | 186 | 50 | 75 | 27.5 | 130/80 | 30 | 22 | F10 | M10*16 | NPTV4” | ||

| PLE-140 | 389 | 173 | 75 | 203 | 60 | 77 | 32 | 130/80 | 30 | 22 | F12 | F10 | M12*20 | M10*16 | |

| PLE-160 | 460 | 198 | 87 | 228 | 60 | 87 | 34 | 130/80 | 30 | 27 | F12 | F10 | M12*20 | M10*16 | |

| PLE-190 | 536 | 230 | 109 | 280 | 65 | 103 | 40 | 130 | 30 | 36 | F14 | M16*24 | |||

| PLE-210 | 537 | 256 | 135 | 306 | 65 | 113 | 40 | 130 | 30 | 36 | F14 | M16*24 | |||

| PLE-240 | 603 | 292 | 155 | 342 | 81 | 130 | 50 | 130 | 30 | 46 | F16 | M20*26 | NPT3g” | ||

| PLE-270 | 730 | 324 | 164 | 374 | 81 | 145 | 50 | 130 | 30 | 46 | F16 | M20*26 | NPTV2” | ||

Specialization in the production of ball valves, butterfly valves, and other specialty valves for various industrial applications.

Certifications of ISO 9001, CE, API 6D, and API 607, ensuring product quality compliance with international standards.

Specialization in the production of pneumatic valve actuators, along with the provision of comprehensive automated control solutions.

Have questions about our valve? Here are some of the most frequently asked questions to help you better understand our products and services. Feel free to contact us for more details!

If you don’t find the answer you’re looking for, feel free to contact us directly—we’re here to assist you every step of the way.

We specialize in industrial valves, including ball valves, butterfly valves, gate valves, and check valves, serving multiple industries, including power generation, petrochemicals, energy storage, marine, and nuclear power.

Our products are certified by ISO9001, API 6D, CE, TSG, CCS, and DNV, meeting international quality and safety standards.

Yes, we offer customized solutions in terms of material, structure, size, and functionality based on our customers' application requirements.

We offer a full lifecycle service, including selection consultation, installation and commissioning, on-site repairs, spare parts supply, and emergency response.

Whether you need valve selection consultation, customized solutions, or after-sales technical support, our team will provide you with fast and professional service.

Email Us