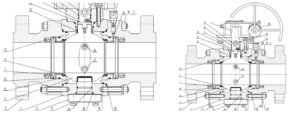

Dual independent seals are employed to ensure the integrity of the valve body connection. Additionally, the superimposed connection structure—featuring a tight metal-to-metal gap—enables the valve to withstand pipeline-induced stresses.

Key Characteristics And Technical Advantages Of Three-Piece Fixed Ball Valve

· Design and size: API 6D, API 608, ASME B16.5.

· Three-piece bolted connection valve body structure, which is convenient for on-site maintenance and maintenance.

· Forged steel valve body, connecting body and valve ball are standard materials to ensure the integrity of the grain structure of the material.

· The support of double independent seals is used to ensure the integrity of the valve body connection, and the superimposed connection structure with a tight gap between the metal and the metal can withstand the stress from the pipeline.

· Double cut-off and discharge valves (DBB).

· The valve has been tested for anti-static electricity.

· The valve has been tested for fire safety and verified by a third-party API 607 with high reliability.

· The main valve is equipped with a manual discharge valve for safe pressure relief.

· The main valve is equipped with a drain/flush plug.

· All fixed ball valves are equipped with a locking device.For valves operated by gearboxes, this locking feature is included in the gear operator.

· All fixed ball valves are equipped with ISO 5211 mounting flanges, which are very easy to install various drive mechanisms.

· The valve meets the low escape standard.

· Automatic pressure relief in the valve cavity: The increased dangerous pressure in the valve cavity is automatically discharged into the pipeline through the included safety discharge device.

· The hardness of the valve body, valve cover, sphere, valve stem and metal valve seat ring materials that have been controlled by appropriate heat treatment, and meet the requirements of NACE MR0175.

Stem Design Features

· The valve features a blowout-proof stem safety structure.

· The stem and retaining shaft are manufactured separately from the valve ball and supported by a sleeve and RPTFE thrust washer, ensuring low operating torque.

· A multi-stage, independent stem packing seal system ensures stem sealing integrity.

· All valves are equipped with an emergency grease injection system for secondary stem sealing.

Seat Design Characteristics

·The valve has an automatic internal self-unloading cavity (DPE design can be realized as required).

· The special high-volume valve seat insert design effectively promotes the scope of use of the material, thereby increasing the life of the valve under different conditions of use.

· The valve seat ring contains an independent graphite seal, which maximizes the sealing under fire conditions.

· All 6” and larger caliber valves (smaller caliber may have special requirements) are equipped with an emergency sealant grease injection system for secondary sealing.

· Under the seat sealant injection pipe fitting is a separate and independent single-way valve.Our valve performs a hydrostatic test on the only check valve used.

· If the pipe fittings for injection fail, there is no need to perform a hydrostatic test on the valve after replacing the pipe fittings.

| Item | Parameters & Standards |

|---|---|

| Size Range | Full bore: 2″ (DN50) ~ 24″ (DN600)Reduced bore: 3″ (DN80) ~ 28″ (DN700) |

| Pressure Rating | American system: Class 150 ~ Class 2500European system: PN16 ~ PN420 |

| Design | API 6D, ASME B16.34 |

| Face-to-Face | API 6D, ASME B16.10 |

| End Connection | Flanged ends (ASME B16.5)Welded ends (ASME B16.34) |

| Flange Dimensions | American system: ASME B16.5Chinese standard: GB/T 9124.2, HB |

| Pressure Test | API 6D, API 598, ISO 17292, GB/T 13927 |

| Pressure/Temperature | ASME B16.34 or GB standards |

Specialization in the production of ball valves, butterfly valves, and other specialty valves for various industrial applications.

Certifications of ISO 9001, CE, API 6D, and API 607, ensuring product quality compliance with international standards.

Specialization in the production of pneumatic valve actuators, along with the provision of comprehensive automated control solutions.

Have questions about our valve? Here are some of the most frequently asked questions to help you better understand our products and services. Feel free to contact us for more details!

If you don’t find the answer you’re looking for, feel free to contact us directly—we’re here to assist you every step of the way.

We specialize in industrial valves, including ball valves, butterfly valves, gate valves, and check valves, serving multiple industries, including power generation, petrochemicals, energy storage, marine, and nuclear power.

Our products are certified by ISO9001, API 6D, CE, TSG, CCS, and DNV, meeting international quality and safety standards.

Yes, we offer customized solutions in terms of material, structure, size, and functionality based on our customers' application requirements.

We offer a full lifecycle service, including selection consultation, installation and commissioning, on-site repairs, spare parts supply, and emergency response.

Whether you need valve selection consultation, customized solutions, or after-sales technical support, our team will provide you with fast and professional service.

Email Us