Inert Primary Seal: Provides the widest range of service conditions. Providing dual sealing on the stem and seat, allowing the use of inert or user-recommended materials.

EF Floating Ball Valve Features and Technical Advantages

· Design and Dimensions: API 6D, API 608, ASME B16.5.

· Packing Gland with Shoulder Bolts: Ensures balanced packing loading and prevents tilting.

· Spring-Loaded Packing: Maintains constant packing loading, eliminating the need for frequent adjustments.

· Independent Multi-Stage Packing: Ensures compliance with stringent low-leakage standards and eliminates the need for stem injection sealant.

· Inert Primary Seal: Provides the widest range of service conditions. Providing dual sealing on the stem and seat, allowing the use of inert or user-recommended materials.

· Unique High-Volume Seat Ring: Provides positive sealing under both low- and high-pressure conditions. The seat ring is designed and tested in accordance with API 6D / ISO 14313 requirements. High-pressure seat testing is performed first, followed by low-pressure seat testing, in the API 6D pressure test sequence, exceeding the lower test requirements of API 598.

Independent Dual Body Seam Seals: A combination of metal-to-metal overlap and tight tolerances ensures the integrity and strength of the body seam seal. The two seals are made of different inert materials (PTFE and graphite), and through a special metal-to-metal joint design, both seals are completely enclosed on all sides.

EF Floating Ball Valve Features and Technical Advantages

· Design and Dimensions: API 6D, API 608, ASME B16.5.

· Packing Gland with Shoulder Bolts: Ensures balanced packing loading and prevents tilting.

· Spring-Loaded Packing: Maintains constant packing loading, eliminating the need for frequent adjustments.

· Independent Multi-Stage Packing: Ensures compliance with stringent low-leakage standards and eliminates the need for stem injection sealant.

· Inert Primary Seal: Provides the widest range of service conditions. Providing dual sealing on the stem and seat, allowing the use of inert or user-recommended materials.

· Unique High-Volume Seat Ring: Provides positive sealing under both low- and high-pressure conditions. The seat ring is designed and tested in accordance with API 6D / ISO 14313 requirements. High-pressure seat testing is performed first, followed by low-pressure seat testing, in the API 6D pressure test sequence, exceeding the lower test requirements of API 598.

·Independent Dual Body Seam Seals: A combination of metal-to-metal overlap and tight tolerances ensures the integrity and strength of the body seam seal. The two seals are made of different inert materials (PTFE and graphite), and through a special metal-to-metal joint design, both seals are completely enclosed on all sides.

Lockdown Feature: Standard on all valves.

·Anti-Static: The valves feature dual anti-static stems, grounded to both the body and ball.

·Wall Thickness: The wall thickness of all valves exceeds ANSI B16.34 requirements, ensuring the appropriate amount of wall thickness between thick and thin sections for optimal flow and cooling, and avoiding shrinkage, a primary cause of shell leaks. The additional wall thickness also meets customer-requested increased corrosion allowances.

·Anti-Blowout Stem: Securely retains the valve stem.

·Automatic Valve Cavity Pressure Relief: An integrated safety vent automatically relieves dangerous pressure buildup within the valve cavity to the pipeline.

Fire-safe: Third-party tested and API 607 certified.

·Upperbody connection plate complies with ISO 5211.

·The hardness of the body, bonnet, ball, and stem materials is controlled through proper heat treatment and meets NACE MR0175 requirements.

Features and Applications

·Low fluid resistance: A full-bore ball valve has virtually no flow resistance.

·Simple structure, compact size, and lightweight.

·Tight and reliable. It has two sealing surfaces, and the ball valve’s sealing surface materials

·A wide range of plastics are used, resulting in excellent sealing and a complete seal. It is also widely used in vacuum systems.

·Easy to operate and open and close quickly. High-performance ball valves can be rotated 90° from fully open to fully closed, facilitating remote control.

·Easy maintenance: The ball valve has a simple structure, and the sealing ring is generally removable, making it easy to remove and replace.

·When fully open or closed, the sealing surfaces between the ball and valve seat are isolated from the media, preventing erosion of the valve sealing surfaces when the media passes through.

·It has a wide range of applications, ranging from diameters as small as a few millimeters to as large as several hundred millimeters, and can be used in applications from high vacuum to high pressure.

·Because the ball valve has a wiping effect during opening and closing, it can be used in media containing suspended solids.

It is widely used in oil refining, long-distance pipelines, chemical industry, papermaking, pharmaceuticals, water conservancy, electric power, municipal administration, steel and other industries.

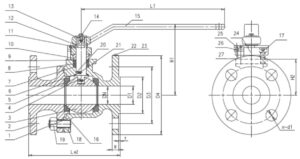

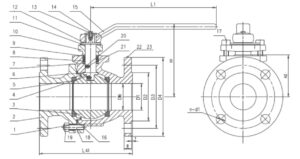

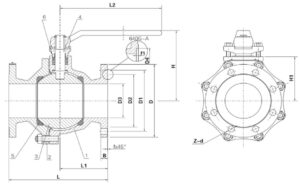

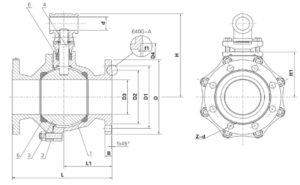

| Item | Specification |

|---|---|

| Size Range | 1/2” (DN15) ~ 8” (DN200) |

| Pressure Rating | American Standard: Class 150 ~ Class 600European Standard: PN16 ~ PN100 |

| Design Standard | API 6D, ASME B16.34, API 608, BS 17292 |

| Face-to-Face | ASME B16.10 / GB/T 12221 / JB 1686 |

| Connection Type | Flanged end and welded end |

| Flange Dimension | American Standard: ASME B16.5Chinese Standard: GB/T 9113.3, JB/T 79.1, HB |

| Pressure Test | API 598 / ISO 17292 / GB/T 13927 |

| Pressure/Temperature Rating | ASME B16.34 / GB Standard |

Specialization in the production of ball valves, butterfly valves, and other specialty valves for various industrial applications.

Certifications of ISO 9001, CE, API 6D, and API 607, ensuring product quality compliance with international standards.

Specialization in the production of pneumatic valve actuators, along with the provision of comprehensive automated control solutions.

Have questions about our valve? Here are some of the most frequently asked questions to help you better understand our products and services. Feel free to contact us for more details!

If you don’t find the answer you’re looking for, feel free to contact us directly—we’re here to assist you every step of the way.

We specialize in industrial valves, including ball valves, butterfly valves, gate valves, and check valves, serving multiple industries, including power generation, petrochemicals, energy storage, marine, and nuclear power.

Our products are certified by ISO9001, API 6D, CE, TSG, CCS, and DNV, meeting international quality and safety standards.

Yes, we offer customized solutions in terms of material, structure, size, and functionality based on our customers' application requirements.

We offer a full lifecycle service, including selection consultation, installation and commissioning, on-site repairs, spare parts supply, and emergency response.

Whether you need valve selection consultation, customized solutions, or after-sales technical support, our team will provide you with fast and professional service.

Email Us